Gas & Flame Detection

-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- Partners

- |

- SPS Blog

- |

- Contact Us

- |

-

Services

Services

-

Productivity

Productivity -

Safety

Safety -

Warehouse Automation

Warehouse Automation

-

-

Industries

Industries

-

Healthcare and Life Sciences

Healthcare and Life Sciences -

Transportation and Logistics

Transportation and Logistics -

Manufacturing

Manufacturing -

Distribution Centers

-

Retail

Retail -

E-Commerce

-

Infrastructure

Infrastructure -

Government

Government -

Aerospace and Defense

-

Electrification

-

-

Support

Support

-

Advanced Sensing Technologies

Advanced Sensing Technologies -

Productivity

Productivity -

Safety

Safety -

Warehouse Automation

Warehouse Automation -

Global Tracking

Global Tracking

-

You are browsing the product catalog for

Gas & Flame Detection

Safety That’s Always on the Lookout! Various gas detection products and solutions designed to protect your workers and your plant

Safety That’s Always on the Lookout

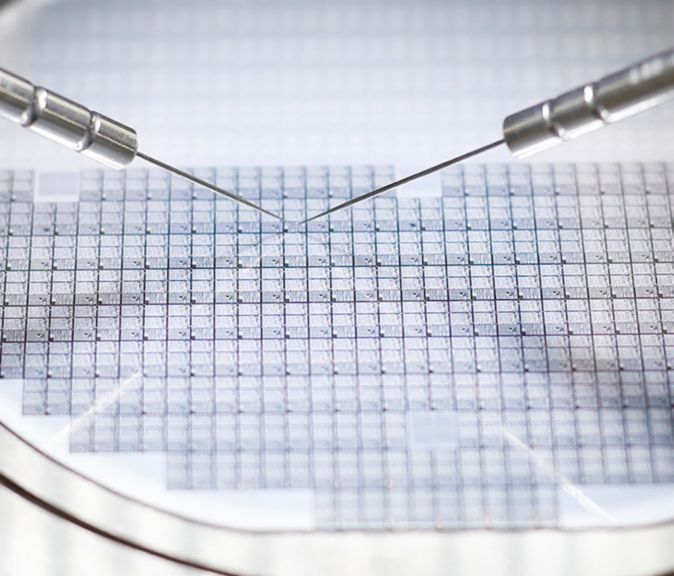

Accidental gas leaks pose a huge threat to properties, environment and human life. Therefore, Honeywell manufactures a full and comprehensive range of gas detection products dedicated to all types of industrial facilities, from smaller boiler rooms to large petrochemical plants and oil refineries.Honeywell’s wide range of technologies and devices – gas detectors, flame detectors, natural gas alarms – provide exceptional protection at every level, ensuring the most favorable coverage, detection, hazard mitigation and life protection.

Get the specific gas detection product you need and benefit from quality, functionality and ease of use. Wherever hostile environments exist, Honeywell will make it a safer workplace for everyone.

Product Finder

Start your search with category name, product name, part number, etc.

Let's Connect!

Sign up to receive exclusive communications from Honeywell including product updates, technical information, new offerings, events and news, surveys, special offers, and related topics via telephone, email, and other forms of electronic communication.

Copyright © 2024 Honeywell International Inc